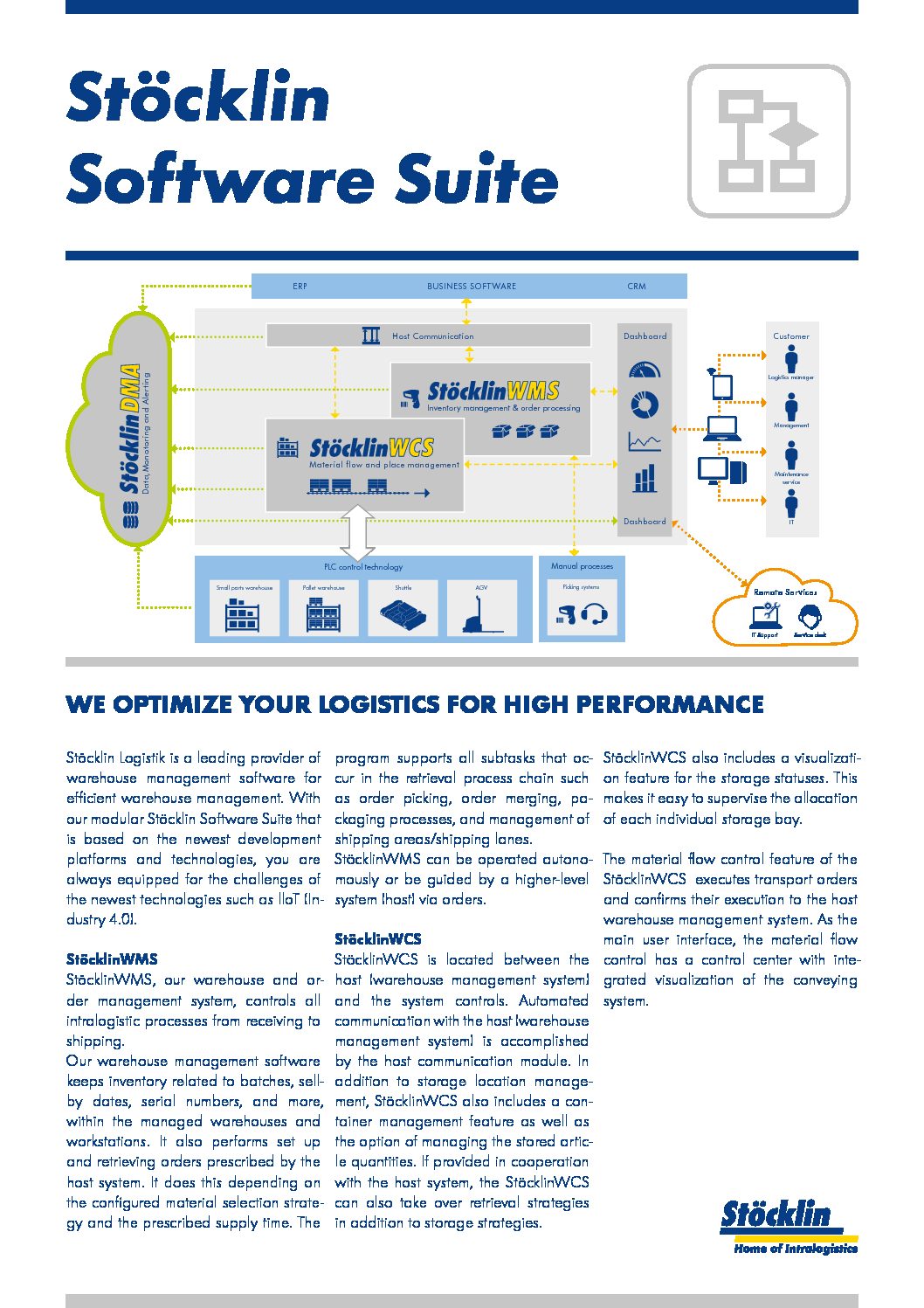

StoecklinWMS: Warehouse Management System

A Warehouse Management System to maximize the

effectiveness of your operations

Stoecklin’s Warehouse Management System

StoecklinWMS, a warehouse and order management system, controls all intralogistic processes from receiving to shipping.

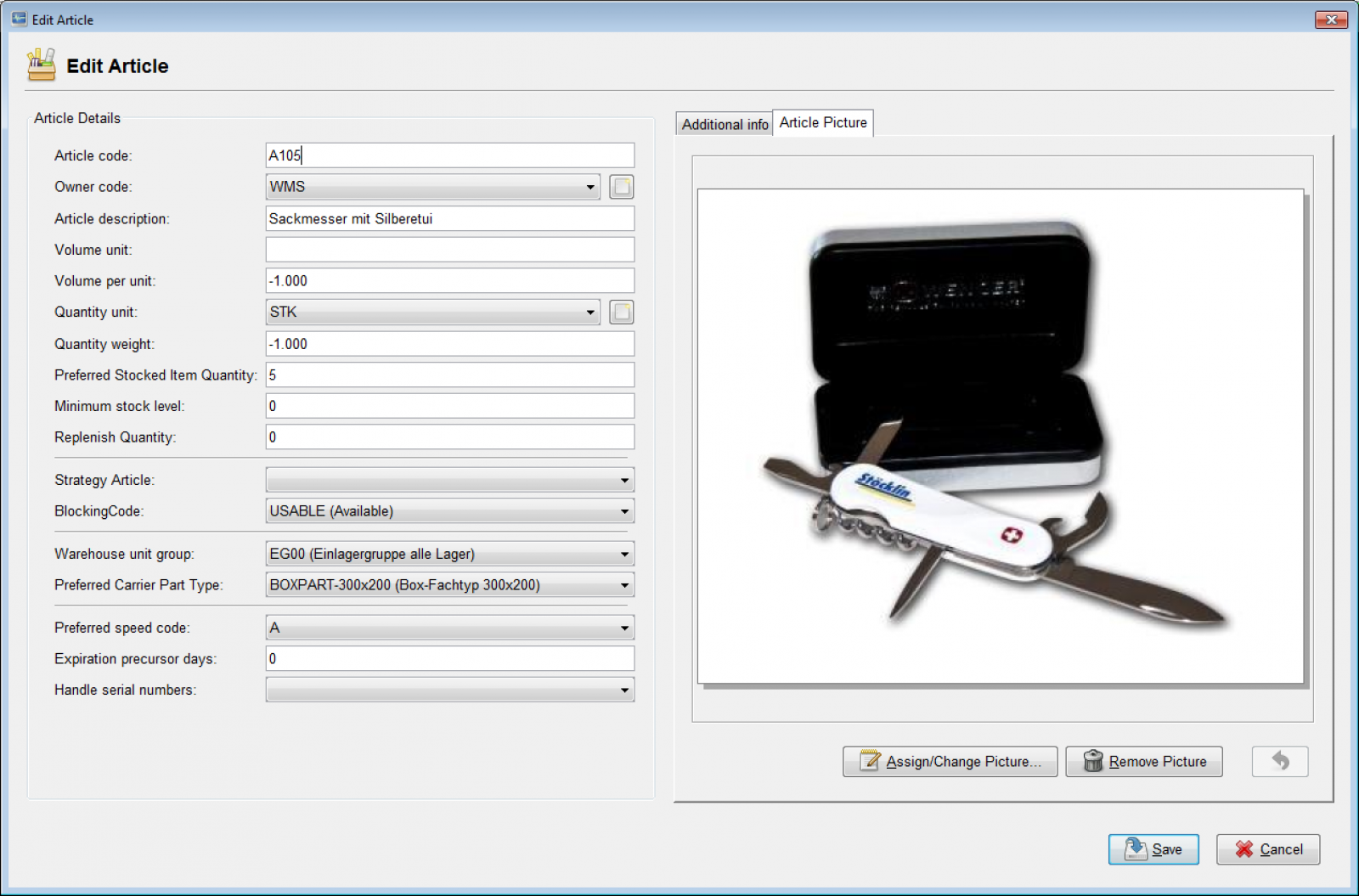

The warehouse and order management system, handles all intralogistic processes between the receiving department and the shipping department. During this process it keeps inventory in the storage facilities in which it is installed with optional features such as keeping track of batches, expiration dates and serial numbers. The StoecklinWMS handles retrieval orders from the host system selecting the most suited material and observing the specified provision time. Retrieval processes as well as picking, consolidation of orders, packaging and provision at the ramp are supported.

The StoecklinWMS can be operated autonomously or controlled by a host system on an order basis.

Standardized logistic processes

- Order management

- Stock management

- Client Management

- Strategies for handling serial numbers, expiration dates, batches, quarantined goods, etc.

- Various types of fully automatic picking such as person to goods, goods to person.

- Use of picking aids such as pick by light, put to light, pick by voice, fork-lift control system among others.

- Standard processes for stock receiving, roll-ins, storage, replenishment, picking, order consolidation, packaging, shipping and inventory

Intuitive User Guidance for your WMS

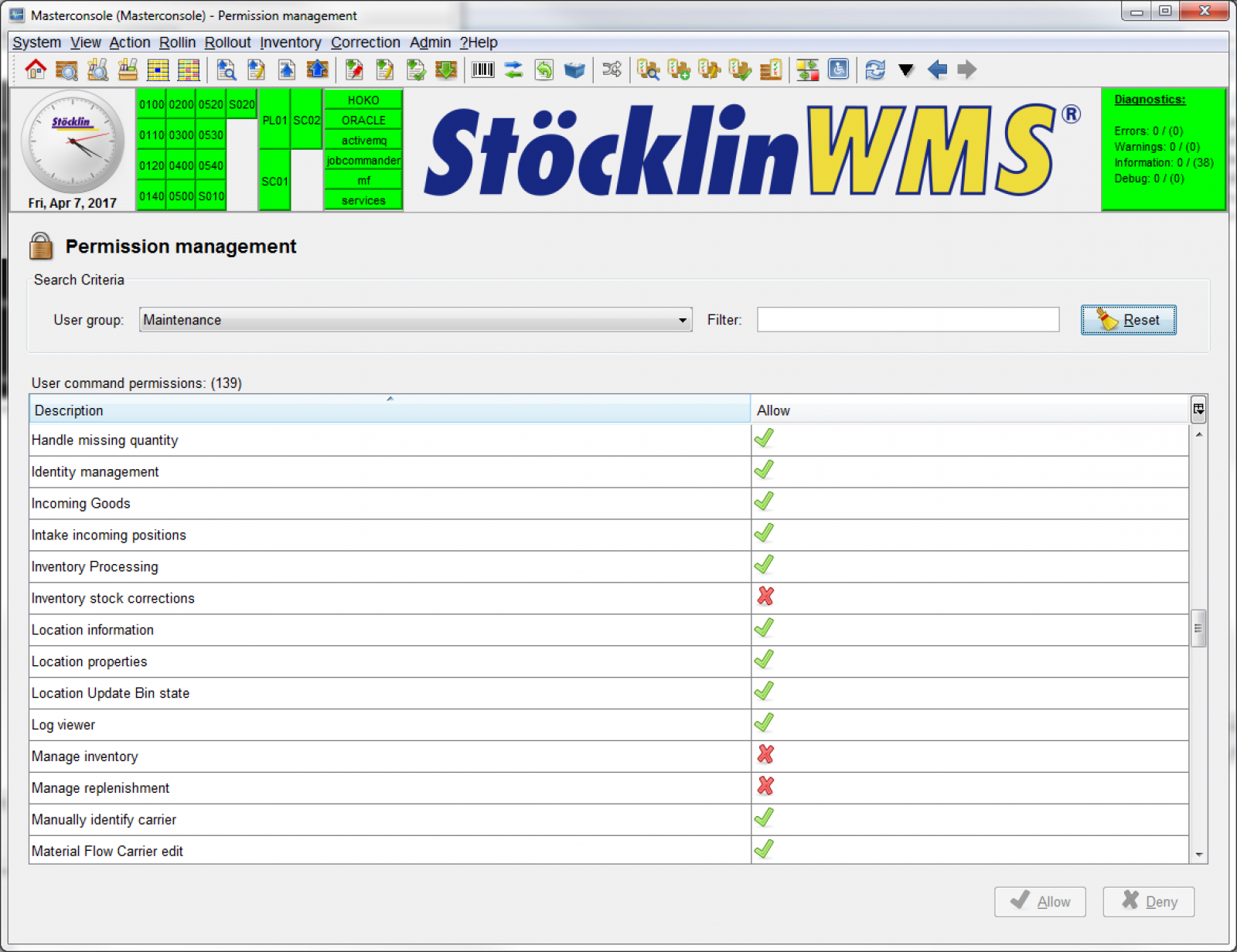

- Comprehensive user management

- Multi-lingual

- Interactive user input designed for optimized process control

- Efficient context-related data access

- Continuous logging of process sequences

Optimized for new systems and upgrades

- Parametrizable processes (adjusting system variables)

- Configurable host interface

- Standardized data acquisition for migration

- Development and realization processes according to GMP (Good Manufacturing Practices)