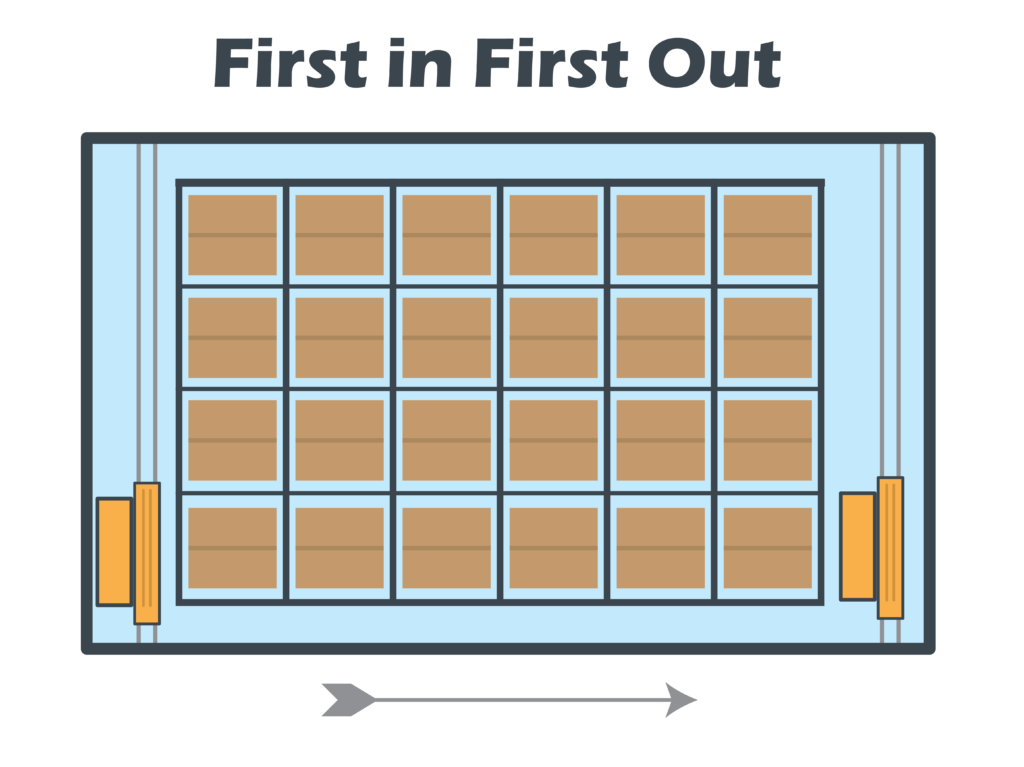

We all know that FIFO, first in/first out, in distribution is used in a variety of industries. For example, grocery, food, pharmaceutical, and even in certain manufacturing, FIFO is the key inventory management system. It is a method for products that have any sort of expiration date.

We all know that FIFO, first in/first out, in distribution is used in a variety of industries. For example, grocery, food, pharmaceutical, and even in certain manufacturing, FIFO is the key inventory management system. It is a method for products that have any sort of expiration date.

However, FIFO in distribution can be held to different degrees of strictness. So we like to think about it as Flexible FIFO.

Strict FIFO in Distribution:

For instance, let’s look at two pallets of medication that are identical except for the fact that one is made an hour later than the other. In a strict FIFO management system, the one that was created 60 minutes before the other (even if it was from the same batch) is the first and must go out before the second.

In a vacuum that doesn’t present any issues. Nevertheless, when in a real-world scenario, problems may crop up depending on your warehouse set-up.

If you have single deep storage there is no concern. You have your first pallet P1 at bay A and the second pallet P2 at Bay B. Your crane can access either with ease.

Let’s say you have double-deep storage. Your crane stores P1 as it comes from manufacturing in Bay A. Then an hour later it stores P2 in the second position of Bay B. Now when you need to access P1 you have to shuffle P2 out of the way and then get P1.

Any shuffling or movement by a crane results in less efficiency and more time.

The system gets even more complicated if you have deep-lane storage.

This type of strict FIFO may be mandated by law or by your individual company. But as you can see it can cause a loss of efficiency. Strict FIFO may dictate you must have single-deep storage throughout your distribution center.

Advantages of FIFO:

The advantages of FIFO are fairly obvious.

- Reduce expiration: When you sell your first produced products first you save money by limiting the amount of “spoilage”.

- Quality Control: It can be easier to track an inferior product. This impact is more evident in non-automated warehouses with a less sophisticated WMS tied to tracking

FIFO by Batch or Flexible FIFO:

In the case of a less strict FIFO or batch FIFO, you can allow small variants to not impact your inventory storage with your automation. This could make your storage and distribution more efficient and perhaps lower your footprint.

You must determine what variation in time still make your products “same”. Is it an hour, a day, a week?

Need to consult with a company that has experience managing these questions? Feel free to reach out and get more information. Contact us.

Recent Comments