News

Stoecklin Logistics Opens New Georgia Location to Support Growth in North America

Located in Marietta, the new facility will house the company's Business Administration and US sales teams to consolidate operations and support strategic growth MARIETTA, Ga. – Jan. 30, 2023 – Stoecklin Logistics, Inc., a leading provider of automated material...

Embracing the Future: Unveiling the Anticipated Trends in Industrial Automation for 2024

As we bid farewell to a dynamic year in warehousing, manufacturing, and processing, the buzz around the application of AI in operations continues to echo. While AI undoubtedly steals the spotlight, let's not overlook the other groundbreaking trends that are poised to...

Stöcklin Logistics Named Recipient of 2023 Top Software & Tech Award

Award honors top software and technology providers that ensure a safe, efficient and reliable global cold food and beverage supply chain. ATLANTA— Food Logistics, the only publication exclusively dedicated to covering the movement of product through the global cold...

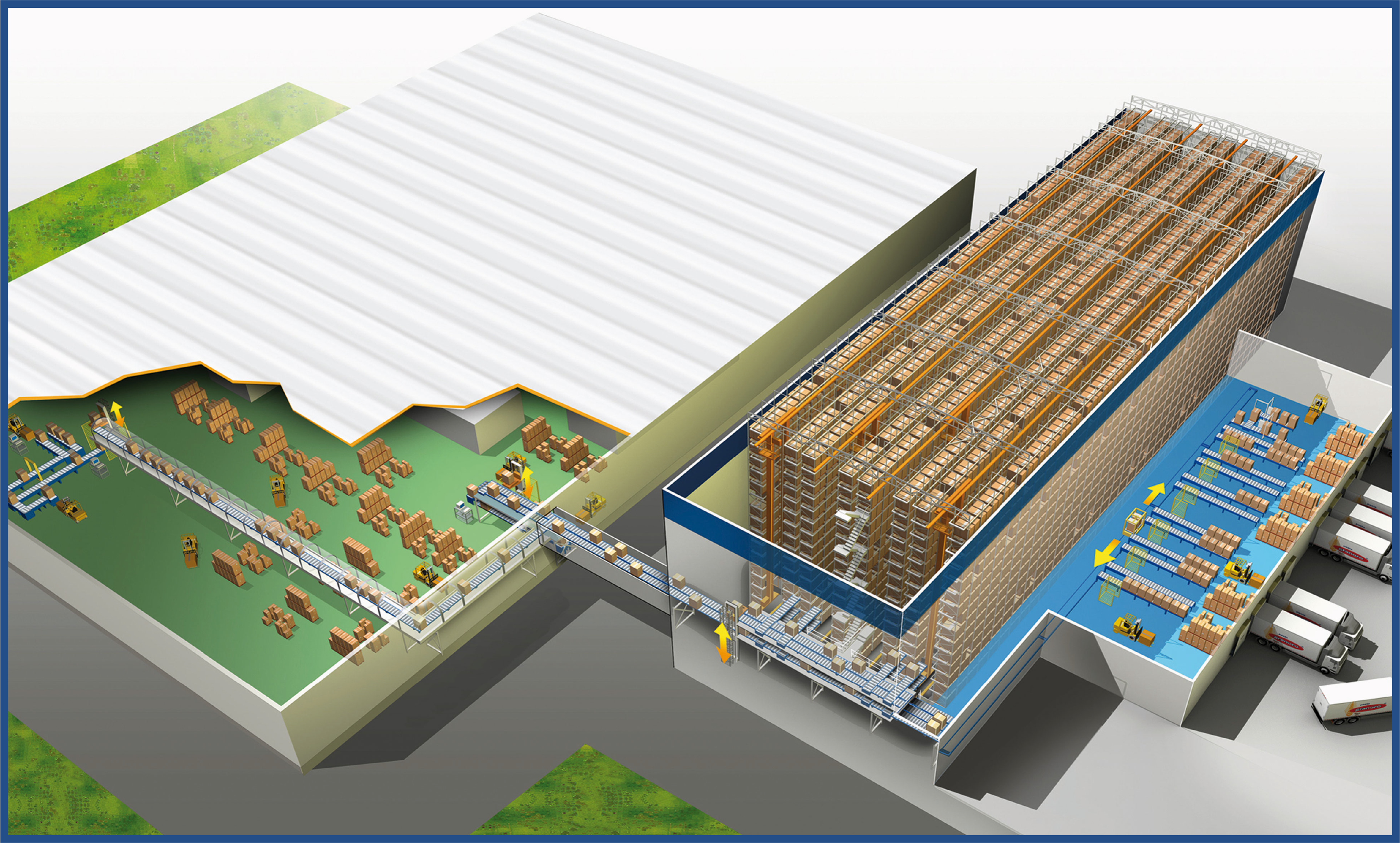

How Automated Product Handling Systems Empower Retailers and Wholesalers in the E-Commerce Era

During the last quarter century, and since the pandemic in particular, e-commerce has emerged as a driving force reshaping the way retailers, wholesalers and suppliers conduct business. With the ever-growing demand for online shopping, businesses are faced with the...

Leveraging Automation to Navigate Regulatory Compliance in Pharmaceuticals

Pharmaceutical companies operate in an environment where even the smallest oversight can have profound consequences, from product safety issues to costly fines and reputational damage. The demand for precision and accountability is high, and automation is a...

Streamlining Efficiency: Six Warehouse Automation Best Practices to Consider

To meet the ever-increasing demands of customers while remaining competitive (and profitable!), warehouse facilities are turning to a wide variety automated solutions. Warehouse robotics and related systems not only reduce labor costs but also enhances accuracy,...

Enhancing Warehouse Visibility with Cloud Supply Chain Technology

A crucial component of an optimized supply chain is the warehouse, where businesses often face the challenge of limited or insufficient product visibility that can lead to inefficiencies, increased costs and customer dissatisfaction. This is where cloud supply chain...

How Automation is Leading the Charge Against Climate Change

The world is at a crucial juncture in the battle against climate change, and innovative solutions are needed now more than ever. Thankfully, automation is emerging as a game-changer in the fight to protect the environment and combat this pressing global challenge....

Transforming Small Load Storage Systems: Maximizing Efficiency and Space

In the world of warehousing, distribution, order fulfillment, and manufacturing, there is a pressing need to store, buffer, and sequence smaller products. From tiny components to larger parts, these items often require a small load storage system. Traditionally,...

Stoecklin Introduces CasePicker Automation Solution to Help Companies Improve Throughput Performance

New system accommodates different size containers to optimize palletizing and depalletizing while ensuring product integrity ATLANTA – Increased demand for fruit and vegetables across retail and foodservice channels is driving suppliers to enhance their supply chains...